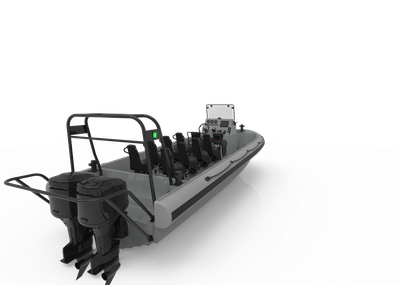

Aquavite 740 custom race rib

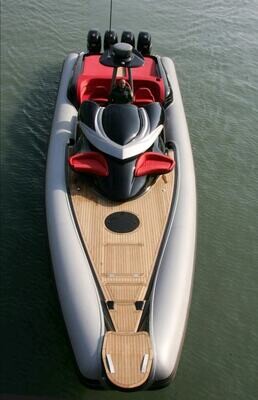

With regards to the deadrise angle - it is a complicated hull - and one we are particuarly proud to have developed. Whilst it is stepped there is also a lot more going into the design than that!

We have designed stepped hulls for many years - but I firmly believe that as a design office we have developed these hull forms for production boats further than others. Most notably our hulls have tapered steps - which stilll gives some of the performance gains - but also most importantly gives a great balance between performance and handling. Certainly if we develop a design for racing only, then the steps are different.

We certainly find that as the craft (as stepped hulls generally do) rides a lot more level the bow sectrions work far more effectively and do there job. Thus it is possible to utilise slightly lower deadrise angles aft and thus aid efficiency again.

Deadrise at Transom

The initial section is of a pad effect type and as such is low deadrise. The main planing section to the main chine is then at 21 deg. We then incorporate an outer chine with the deadrise angle between the two chines being 40 deg. Overall there is a mean deadrise angle of 22 deg. The main panel also has some camber added to it - thus actually giving it variable deadrise.

The inner section aids efficiency, main section gives the majority of lift and determines the ride of the craft - and the outer section really comes into play in rough conditions, turning - whilst adding extra beam to the craft.

In bow sections the deadrise goes up to a maximum of 48 deg - mean. By this stage the pad has been faired out and the main planing section and outer section merge into one as the two surfaces become one.